- STUDY-PRODUCT DEVELOPMENT

- LASER CUTTING

- ELECTROSTATIC PAINTING

- CONFIGURATION

- PRODUCT SHIPMENT

- WELD

- TRADE

- CUTTING TUBE WITH LASER

Study – Product development

Every new product is a challenge for us. From finding the best and most qualitative material to the final process of its implementation, the study department (RND) of PANMETAL carefully controls, improves and studies each stage of production. That is why the product that is finally delivered to the customer is unique, whose copyright belongs to him. Starting from the study of the project, the correct planning and its design, we first produce a sample for the necessary suitability check, we plan its production and then we execute the order and its implementation. Therefore, the design includes:

- Redesigning existing products while improving quality and price,

- The creation of new products, using technology, to meet new areas of application and more needs,,

- Laser cutting.

Throughout this process, PANMETAL is in close cooperation and communication with the customer, to achieve the best result that will fully meet his needs.

Κοπή Laser

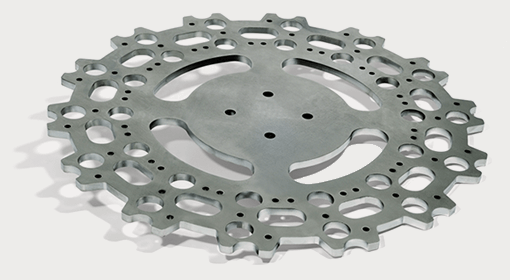

Laser cutting is one of the most creative and advanced technological stages of Panmetal production. It offers maximum convenience, speed, efficiency and flexibility in construction, while being applied in many industrial branches. Laser technologies have great advantages in the production of works, such as replacement or optimization of many traditional sheet metal elements and enable the cutting with precision of multiple profiles in:

- Iron, steel and refractory.

- Cold-rolled iron plate (DCP), galvanized, perforated, embossed (chequered – tear drop).

- Stainless steel

- Brass, copper

- Aluminum

From the simplest components to the most complex shapes and forms, laser technology is applied both in the stage of preparation and in the construction of mass batches. The possibilities offered by the technology of fiber laser machines are much greater than the possibilities offered by conventional machines and they give maximum productivity in a minimum of time. With a small cutting beam trace, insertion of parts by means of a computer and cutting speed into thin sheets, from 50% to 300% higher than in conventional machines.

Technical characteristics:

- Maximum cutting dimension: 4000X2000 mm

- Maximum steel thickness: 25 mm

- Maximum thickness of special Hardox steel: 25 mm

- Maximum galvanized steel thickness: 5 mm

- Maximum thickness of stainless steel: 20 mm

Trumpf Fiber Laser 3040

The new generation fiber laser machine was added to our equipment in November 2016. It is characterized by its amazing speed and its excellent cutting result.

Machine features: Table size: 4000X2000

Cutting speed: 140 meters / minute (simultaneously on the X and Y axes).

Cutting accuracy: 0.001mm

Trumpf Laser 3040 TruFlow 4000

- Advantages of laser technology.

- Minimal thermal stress at the cutting points.

- Design flexibility in changing dimensions and immediate costing of the product.

- Dimensional accuracy and unlimited repetition of designs.

- Fully automated systems that allow complete control of production.

- Higher cutting speed than with other methods.

- Save time and money.

- High cutting accuracy (0.1mm).

- Clean, smooth and quality surface, without the need for further processing and additional finishing (grinding - hole cleaning).

- Maximum utilization and saving of material (Nesting).

- Vertical cutting surface.

- Engraving the pieces with great precision.

- Quality of construction: We have a high level of quality due to the high cutting accuracy and the perfect cutting surface.

In laser machines we process the following materials:

- Iron, steel, refractory, abrasion resistant metal, painted steel.

- Cold-rolled iron plate (DCP), galvanized, perforated, chequered.

- Stainless steel.

- Brass, copper.

- Aluminum.

Cutting possibilities:

- Stainless steel 0.5: 15mm

- Aluminum 0.5: 12mm

- Steel 0.5: 20mm

- Bronze 0.5: 6mm

- Copper 0.5: 6mm

- Titanium 0.5: 4mm

- Special Steels 0.5: 10mm

- Dimensions of cutting sheets: 4000 x 2000mm

ELECTROSTATIC PAINTING

Electrostatic painting is a key activity of Panmetal, to which we pay special attention, as it is applied to several constructions and products. After preparing the surfaces adequately with the proper use of chemical methods, we then ensure uniform coverage with state-of-the-art spray guns. The special paint powder is applied on the profiles of aluminum, iron alloys, railings and metal parts, through a cooperating production network, so that the result is always flawless.

Shaping

The modern tools available by Panmetal are a guarantee for the desired result of the final product, regardless of the production number. At the same time, our know-how guarantees the absolute accuracy in its formatting. In addition, the experienced engineers of PANMETAL have at their disposal the appropriate tools, the pre-simulation of the shaping, the dynamic thickness measurement by the machine and the compensation of the resets during the shaping. With these factors in place, the speed and efficiency of the process is increased, and the perfect formatting is ensured, from the first to the last piece of the order. This is the so-called "straining". Knowing the ever-increasing needs of our customers, in terms of special precision pieces, Panmetal offers the four CNC press brakes, which are ideal for complex types of shaping, up to six meters in length. At the same time, the special software that calculates each shaping, ensures the accuracy of the cutting extensions and bending points, without the prior intervention of the customer in calculating the dimensions and the presses.

4 Press brakes

Panmetal has four press brakes at its disposal, which are ideal for all types of straining. The recent addition to our mechanical equipment is the new press brake model, the top TruBend 5230 230 TN CNC. The features of this modern machine allow the shaping of complex components with ease and precision, depending on its incredible speed. The result of the above is the combination of the best price with the extremely high quality final product. The special software of this machine calculates the presses in advance and guarantees the construction of the right component from the first part. The possibility of iron plate shaping reaches up to 25mm. The following are the models of the press brakes available by Panmetal:

- 1 4metre press brake 300 ton

- 1 6metre press brake ton

- 1 4metre press brake ton

- 1 3metre press brake ton

3 Shears

For the execution of orders that do not require cutting by means of a laser machine, we use three shears of dimensions 2m, 4m and 6m, with the possibilities of cutting reaching up to 12mm.

Cylinder

For the shaping of the metal sheets we use the IMCAR cylinder.

Punch

Panmetal uses the Geka Puma 55, which is a 55-ton hydraulic shear with a cylinder, with an additional guide for precision drilling and a powerful and precise shaft system to prevent deformation.

Product shipment

When the production process reaches the final stage of the shipment, then the safety and maintaining the integrity of each product are a priority and commitment of PANMETAL. We ensure the protection of our products during their distribution to their final destinations, providing suggestions and solutions specifically tailored to them, depending on their specific features. The distribution of the final products is done in collaboration exclusively with reliable suppliers that have certified materials.

WELD

Panmetal applies alternative welding methods for the best possible result, both aesthetically and functionally. The elements that allow us to put the above into effect are our investments in state-of-the-art infrastructure, state-of-the-art equipment, securing certified materials, testing in special processing methods and, finally, having specialized personnel with extensive experience and know-how. For welding we use the following smart, modular and manual equipment: TIG welding from 0.5mm to 16mm of common steel and stainless steel. MIG welding from 0.4mm to 25mm of common steel, stainless steel and aluminum. Both meet the most demanding needs of our customers, provide the most appropriate technical solutions, while greatly increasing productivity.

WELD

Panmetal provides high quality welding services to its customers, as it always uses the best and most appropriate way for it, depending on the requirements created for each order.

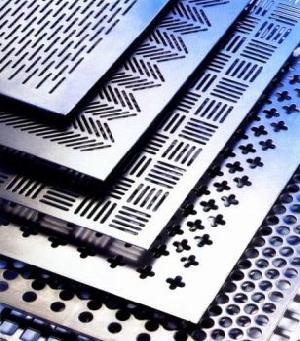

TRADE

For the needs of trade, PANMETAL has ready-made construction products for processing and use, always in collaboration with top suppliers who are leaders in this field. These products are:

• Hot-rolled sheets with embossed surface.• Black, pickled, hot-rolled sheets.

• Galvanized, cold-rolled sheets of pre-painted and plasticised iron plate.

• Hot-rolled iron plates for construction.

• Galvanized, corrugated and trapezoidal iron plates.

• Elongated, galvanized hollow unpainted beams.

• Pipes.

• Panels.

In any case, our goal is to offer each customer those targeted materials that perfectly suit his needs and to respond precisely to them.

Chequered and tear drop iron plate

Hollow profiles – Hollow structural sections

Perforated iron plates

Iron plates of different types and qualities:

- Hot-rolled

- Cold-rolled

- Galvanized

- Aluminum

- Stainless steel

TruLaser Tube 3000 fiber: Latest generation Laser Cutter

The world is evolving. High growth rates require constant mass production of products, a wide variety of materials with obvious cost reductions. Products that include metal pipes and profiles are used everywhere – from mechanical engineering and manufacturing systems to the furniture industry. Laser cutters have opened up new design possibilities. The laser pipe cutting method is now a highly efficient and flexible pipe cutting processing method, applied in many industrial sectors. Metal cutting lasers have the ability to make profile cuts in round, square, oval, triangular tubes. They also provide the ability to cut pipes and metals with great precision into extremely complex shapes. In addition, laser cutters offer the possibility of any type of contour in tubes and profiles with the maximum possible accuracy and design functionality, perfect alignment and flexibility due to the incredible detail that only metal cutting lasers offer. Finally, laser cutters can cut various metals such as common steel 8mm, stainless steel 4mm, aluminum 4mm, copper - brass 3mm. Thus, the designers of these products have turned to the technology of laser cutting of pipes, due to the unique advantages it offers. PANMETAL, having full knowledge of this development, welcomed to its facilities the new reliable and accurate laser for cutting pipes, Trulaser tube 3000 Fiber. A laser cutter machine that covers a wide range of applications such as profiles, round tubes and flat rods, while allowing flexible processing of tubes and profiles, replacing conventional tube processing stages such as saws and processing centers. The TruLaser Tube 3000 fiber tube cutting laser can cut pipes with a diameter of up to 152mm and profiles with an outer circumference of up to 170 mm. The automatically centered holding system of this laser cutter is designed to hold the product in the correct position during processing, while it automatically adjusts to the dimensions of the tube without the need for any manual adjustment by the operator. The TruLaser Tube 3000 fiber tube cutting laser is also equipped with other important automatic functions and settings. The AdjustLine function of this tube cutting laser adjusts the cutting parameters at the touch of a button in order to ensure reliable cutting even regarding lower quality materials. The SeamLine Tube function of the TruLaser Tube 3000 fiber laser cutter detects welding seams as well as scratches on the inside and outside of the pipe surface, helping the operator to check if the pipes are correctly installed in the machine and that the welding seam is in the desired position in the final product. This laser tube cutting machine with its creative profile design saves time and offers technical advantages such as: optimization of individual parts and spare parts, extremely high accuracy, increased delivery speed and reduced costs. A reliable user-friendly laser cutter that represents an economical solution for medium and small batches. Laser pipe cutting is the advanced technology of flat machines. In combination with its special software, product automation welcomes the new generation of production units. With an ideal application in furniture, in shop equipment either in individual projects or in mass production, and in industry, for mass production of high quality components, TruLaser Tube 300 laser cutter automation solutions contribute significantly to the modernization of production as they replace conventional ways of pipe processing and optimize many elements traditionally made of sheet metal.

Technical characteristics of the laser cutter TruLaser Tube 3000 fiber:

The TruLaser Tube 3000 fiber laser cutter is easy to use with a special software. It has an easily adjustable tube holder for all geometries and diameters. This particular tube cutting laser also recognizes seam lines externally and internally for automatic, correct pipe alignment. Finally, the laser cutter TruLaser Tube 3000 fiber delivers high quality results without adjustments with reliable tightening of all tubes.

To see the technical characteristics of the machine press HERE

- Αντιγραφή.jpg)