- ΜΕΛΕΤΗ-ΣΧΕΔΙΑΣΜΟΣ ΠΡΟΪΟΝΤΩΝ

- ΚΟΠΗ LASER

- ΗΛΕΚΤΡΟΣΤΑΤΙΚΗ ΒΑΦΗ

- ΔΙΑΜΟΡΦΩΣΗ

- ΑΠΟΣΤΟΛΗ ΠΡΟΪΟΝΤΟΣ

- ΣΥΓΚΟΛΛΗΣΗ

- ΕΜΠΟΡΙΟ

- ΚΟΠΗ ΣΩΛΗΝΩΝ ΜΕ LASER

ΜΕΛΕΤΗ - ΣΧΕΔΙΑΣΜΟΣ ΠΡΟΪΟΝΤΟΣ

Η μελέτη και ο σχεδιασμός νέων προϊόντων αποτελούν για εμάς μια καθημερινής πρόκληση. Από την εύρεση της καλύτερης, κατάλληλης και πιο ποιοτικής ύλης μέχρι το τελικό στάδιο της υλοποίησής του, το τμήμα μελέτης (Research & Development) της Panmetal ελέγχει, βελτιώνει και μελετά με τη μέγιστη προσοχή κάθε βήμα της παραγωγής. Αυτό έχει ως αποτέλεσμα το προϊόν που παραδίδεται στον πελάτη να είναι μοναδικό και τα πνευματικά του δικαιώματα να ανήκουν στον ίδιο. Ακολουθώντας όλα τα αναγκαία βήματα για τη δημιουργία κάθε έργου που αναλαμβάνουμε, ξεκινάμε από τη μελέτη του, το σωστό προγραμματισμό του και τον σχεδιασμό του. Η διαδικασία αυτή έχει ως αποτέλεσμα την παραγωγή ενός δείγματος για τον απαραίτητο έλεγχο καταλληλότητας. Με τον έλεγχο αυτό να ολοκληρώνεται, προγραμματίζουμε την παραγωγή του και εκτελούμε την παραγγελία και υλοποίησή του. Συνεπώς, ο σχεδιασμός περιλαμβάνει τα εξής βήματα:

- Tον ανασχεδιασμό των ήδη υπαρχόντων προϊόντων με ταυτόχρονη βελτίωση της ποιότητας και της τιμής,

- Tη δημιουργία νέων προϊόντων, με την αξιοποίηση της τεχνολογίας, για την κάλυψη νέων πεδίων εφαρμογής και περισσότερων αναγκών,

- Την κοπή με laser.

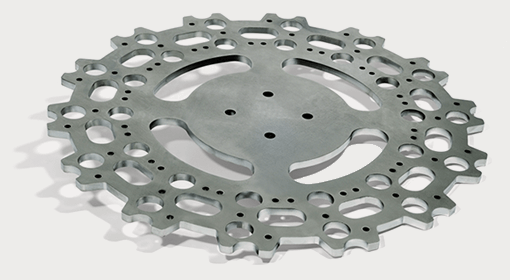

Κοπή Laser

Η κοπή με laser είναι ένα από τα πιο δημιουργικά και προηγμένα τεχνολογικά στάδια παραγωγής της Panmetal. Προσφέρει μέγιστη ευκολία, ταχύτητα, αποτελεσματικότητα και ευελιξία στην κατασκευή, ενώ παράλληλα εφαρμόζεται σε πολλούς βιομηχανικούς κλάδους. Οι τεχνολογίες laser διαθέτουν μεγάλα πλεονεκτήματα στην παραγωγή έργων, όπως αντικατάσταση ή βελτιστοποίηση πολλών παραδοσιακών στοιχείων από μεταλλικά ελάσματα και δίνει τη δυνατότητα κοπής με ακρίβεια πολλαπλών προφίλ σε:

- Σίδερο, χάλυβα, πυρίμαχα,

- Λαμαρίνα DCP, γαλβανιζέ, διάτρητη, ανάγλυφη (κριθαράκι- μπακλαβωτή),

- Ανοξείδωτο χάλυβα

- Ορείχαλκο, χαλκό

- Αλουμίνιο

Η τεχνολογία laser εφαρμόζεται τόσο στο στάδιο της προπαρασκευής, όσο και της κατασκευής μαζικών παρτίδων και από τα πιο απλά εξαρτήματα μέχρι και τα πιο περίπλοκα σχήματα και μορφές. Οι δυνατότητες, δε, που προσφέρει η τεχνολογία των μηχανών fiber laser είναι πολύ μεγαλύτερες σε σχέση με τις συμβατικές μηχανές και δίνουν τη μέγιστη παραγωγικότητα σε ελάχιστο χρόνο. Με μικρό ίχνος δέσμης κοπής, ένθεση τμημάτων μέσω υπολογιστή και ταχύτητα κοπής σε λεπτά ελάσματα, από 50% έως 30%.

Τεχνικά χαρακτηριστικά:

- Μέγιστη διάσταση κοπής: 4000X2000 mm

- Μέγιστο πάχος χάλυβα: 25 mm

- Μέγιστο πάχος ειδικού χάλυβα Hardox: 25 mm

- Μέγιστο πάχος γαλβανιζέ: 5 mm

- Μέγιστο πάχος ανοξείδωτου χάλυβα: 20 mm

Trumpf Fiber Laser 3040

Το μηχάνημα νέας γενιάς fiber laser προστέθηκε στον εξοπλισμό μας το Νοέμβριο του 2016. Χαρακτηρίζεται από τις εκπληκτικές ταχύτητές του και το άριστο αποτέλεσμα κοπής.

Χαρακτηριστικά μηχανήματος:Μέγεθος τραπεζιού: 4000Χ2000

Ταχύτητα κοπής: 140 μέτρα/λεπτό (ταυτόχρονα στους άξονες Χ και Υ).

Ακρίβεια κοπής: 0,001mm

Trumpf Laser 3040 TruFlow 4000

- Πλεονεκτήματα της τεχνολογίας Laser

- Ελάχιστη θερμική καταπόνηση στα σημεία κοπής.

- Ευελιξία σχεδιασμού στην αλλαγή διαστάσεων και άμεση κοστολόγηση του προϊόντος.

- Ακρίβεια διαστάσεων και απεριόριστη επανάληψη σχεδίων.

- Πλήρως αυτοματοποιημένα συστήματα που επιτρέπουν τον απόλυτο έλεγχο της παραγωγής.

- Μεγαλύτερη ταχύτητα κοπής σε σχέση με άλλες μεθόδους.

- Εξοικονόμηση χρόνου και χρημάτων.

- Μεγάλη ακρίβεια κοπής (0.1mm).

- Καθαρή, λεία και ποιοτική επιφάνεια, χωρίς να χρειάζεται περαιτέρω επεξεργασία και επιπρόσθετο φινίρισμα (τρόχισμα - καθάρισμα οπών).

- Μέγιστη εκμετάλλευση και εξοικονόμηση υλικού (Nesting).

- Κάθετη επιφάνεια κοπής.

- Χάραξη των τεμαχίων με μεγάλη ακρίβεια.

- Ποιότητα κατασκευής: Διαθέτουμε υψηλό επίπεδο ποιότητας λόγω της μεγάλης ακρίβειας κοπής και της τέλειας επιφάνειας κοπής.

Στα μηχανήματα Laser κατεργαζόμαστε τα εξής υλικά:

- Σίδερο, χάλυβας, πυρίμαχος, αντιτριβής, βαμμένος χάλυβας

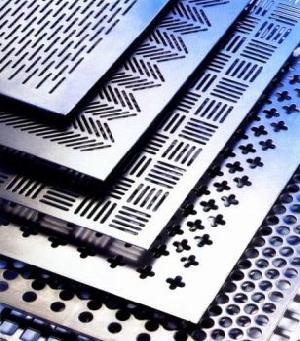

- Λαμαρίνα DCP, γαλβανιζέ, διάτρητη, κριθαράκι

- Ανοξείδωτος χάλυβας

- Ορείχαλκος, χαλκός

- Αλουμίνιο

Δυνατότητες κοπής:

- ΑΝΟΞΕΙΔΩΤΟΣ ΧΑΛΥΒΑΣ 0,5…15mm

- ΑΛΟΥΜΙΝΙΟ 0,5…12mm

- ΧΑΛΥΒΑΣ 0,5…20mm

- ΜΠΡΟΥΤΖΟΣ 0,5…6mm

- ΧΑΛΚΟΣ 0,5…6mm

- ΤΙΤΑΝΙΟ 0,5…4mm

- ΕΙΔΙΚΟΙ ΧΑΛΥΒΕΣ 0,5…10mm

- ΔΙΑΣΤΑΣΕΙΣ ΦΥΛΛΩΝ ΚΟΠΗΣ 4000 x 2000mm

Ηλεκτροστατική Βαφή

Η ηλεκτροστατική βαφή είναι μια βασική δραστηριότητα της Panmetal, στην οποία δίνουμε τη δέουσα προσοχή, καθώς εφαρμόζεται σε μια σειρά από κατασκευές και προϊόντα. Αφού προετοιμάσουμε τις επιφάνειες σωστά με την κατάλληλη χρήση χημικών μεθόδων, στη συνέχεια εξασφαλίζουμε την ομοιόμορφη κάλυψη με υπερσύγχρονα πιστόλια ψεκασμού. Η ειδική πούδρα βαφής εφαρμόζεται πάνω στα προφίλ αλουμινίου, κραμάτων σιδήρου, κάγκελων και μεταλλικών εξαρτημάτων, μέσω ενός συνεργαζόμενου δικτύου παραγωγής, ώστε το αποτέλεσμα να είναι πάντα άψογο.

Διαμόρφωση

Τα σύγχρονα εργαλεία που διαθέτει η Panmetal αποτελούν εγγύηση για το επιθυμητό αποτέλεσμα του τελικού προϊόντος, ανεξαρτήτως αριθμού παραγωγής. Παράλληλα η τεχνογνωσία μας εγγυάται την απόλυτη ακρίβεια στη μορφοποίησή του. Επιπλέον, οι έμπειροι μηχανικοί της ΠΑΝΜΕΤΑΛ, έχουν στη διάθεσή τους τα κατάλληλα εργαλεία, την εκ των προτέρων προσομοίωση των διαμορφώσεων, τη δυναμική μέτρηση πάχους από τη μηχανή και την αντιστάθμιση των επαναφορών κατά τη διαμόρφωση. Με αυτούς τους παράγοντες σε ισχύ, αυξάνεται η ταχύτητα και η αποδοτικότητα της διαδικασίας και εξασφαλίζεται η άψογη μορφοποίηση, από το πρώτο μέχρι το τελευταίο τεμάχιο της παραγγελίας. Αυτό είναι το λεγόμενο “στραντζάρισμα”. Γνωρίζοντας τις συνεχώς αυξανόμενες ανάγκες των πελατών μας, όσον αφορά τα ειδικά τεμάχια ακριβείας, η Panmetal θέτει στη διάθεσή τους τις τέσσερις CNC στράντζες, οι οποίες είναι ιδανικές για τα πολύπλοκα είδη διαμορφώσεων, σε μήκος έως έξι μέτρα. Παράλληλα, το ειδικό λογισμικό που υπολογίζει την κάθε διαμόρφωση, εξασφαλίζει την ακρίβεια των αναπτυγμάτων κοπής και των σημείων κάμψης, χωρίς την εκ των προτέρων παρέμβαση του πελάτη ως προς τον υπολογισμό των διαστάσεων και πατημάτων.

4 Στράντζες

Η Panmetal έχει στη διάθεσή της τέσσερις στράντζες, οι οποίες καθίστανται ιδανικές για όλων των ειδών τα στραντζαρίσματα. Η πρόσφατη προσθήκη στο μηχανολογικό μας εξοπλισμό αποτελεί το νέο μοντέλο στραντζόπρεσσας, η κορυφαία TruBend 5230 230 TN CNC. τα χαρακτηριστικά αυτής της σύγχρονης μηχανής επιτρέπουν τη διαμόρφωση πολύπλοκων εξαρτημάτων με ευκολία και ακρίβεια, σε συνάρτηση με τις απίστευτες ταχύτητες που διαθέτει. Το αποτέλεσμα των παραπάνω, αποτελεί το συνδυασμό της καλύτερης τιμής με το εξαιρετικά ποιοτικό τελικό προϊόν. Το ειδικό software της μηχανής αυτής, υπολογίζει τα πατήματα εκ των προτέρων και εγγυάται την κατασκευή του σωστού εξαρτήματος από το πρώτο κομμάτι. Η δυνατότητα διαμόρφωση λαμαρίνας φτάνει έως και τα 25mm. Παρακάτω παρατίθενται τα μοντέλα των στραντζανόπρεσσων που διαθέτει η Panmetal:

- 1 στράντζα 4μετρη Trubend 5230 230 ΤΝ CNC

- 1 στράντζα 4μετρη Karmet 4100 300 TN TORO PRO CNC

- 1 στράντζα 4μετρη Baykal 300 TN NC

- 1 στράντζα 6μετρη Adira 200 TN NC

3 Ψαλίδια

Για την εκτέλεση παραγγελιών που δεν απαιτούν κοπή σε μηχάνημα laser, χρησιμοποιούμε τρία ψαλίδια διαστάσεων 2m, 4m και 6m, με τις δυνατότητες κοπής να φτάνουν έως και 12mm.

Κύλινδρος

Για τη διαμόρφωση των ελασμάτων, χρησιμοποιούμε τον κύλινδρο της IMCAR.

Ζουμπάς

Η Panmetal χρησιμοποιεί το Geka Puma 55, το οποίο είναι μια υδραυλική διάτμηση 55 τόνων που διαθέτει κύλινδρο με επιπλέον οδηγό για διάτρηση ακριβείας και ένα ισχυρό και ακριβές σύστημα άξονα για αποφυγή παραμορφώσεων.

Αποστολή Προϊόντος

Όταν η παραγωγική διαδικασία φτάσει στο τελικό στάδιο της αποστολής, τότε η ασφάλεια και η διατήρηση της ακεραιότητας του κάθε προϊόντος αποτελούν προτεραιότητα και δέσμευση της ΠΑΝΜΕΤΑΛ. Εξασφαλίζουμε την προστασία των προϊόντων κατά τη διανομή τους στους τελικούς προορισμούς, παρέχοντας προτάσεις και λύσεις ειδικά προσαρμοσμένες σε αυτά, ανάλογα τις ιδιαιτερότητές τους. Η διανομή των τελικών προϊόντων γίνεται σε συνεργασία αποκλειστικά με αξιόπιστους προμηθευτές που φέρουν πιστοποιημένα υλικά.

ΣΥΓΚΟΛΛΗΣΗ

Η Panmetal εφαρμόζει εναλλακτικές μεθόδους συγκόλλησης για το καλύτερο δυνατό αποτέλεσμα, τόσο από αισθητικής πλευράς, όσο και λειτουργικής. Τα στοιχεία που μας επιτρέπουν να βάζουμε σε ισχύ τα παραπάνω είναι οι επενδύσεις μας σε υπερσύγχρονες υποδομές, εξοπλισμό τεχνολογίας αιχμής, εξασφάλιση πιστοποιημένων υλικών, δοκιμή σε ειδικές μεθόδους κατεργασίας και, τέλος, διάθεση εξειδικευμένου προσωπικού με μεγάλη εμπειρία και τεχνογνωσία. Για τις συγκολλήσεις χρησιμοποιούμε τον εξής έξυπνο, σπονδυλωτό και χειροκίνητο εξοπλισμό: Ηλεκτροσυγκόλληση TIG από 0,5mm έως 16mm σε κοινό χάλυβα και inox. Ηλεκτροσυγκόλληση MIG από 0,4mm έως 25mm σε κοινό χάλυβα, inox και αλουμίνιο. Αμφότεροι καλύπτουν και τις πιο απαιτητικές ανάγκες των πελατών μας, παρέχουν τις πλέον κατάλληλες τεχνικές λύσεις, ενώ αυξάνουν σε μεγάλο βαθμό την παραγωγικότητα.

ΣΥΓΚΟΛΛΗΣΗ

Η Panmetal παρέχει υψηλού επιπέδου υπηρεσίες συγκόλλησης των εξαρτημάτων των πελατών της, καθώς χρησιμοποιεί πάντα τον βέλτιστο και καταλληλότερο τρόπο για αυτή, αναλόγως των απαιτήσεων που δημιουργούνται για την κάθε παραγγελία.

ΕΜΠΟΡΙΟ

Για τις ανάγκες του εμπορίου, η ΠΑΝΜΕΤΑΛ διαθέτει έτοιμα κατασκευαστικά προϊόντα προς μεταποίηση και χρήση, σε συνεργασία πάντα με κορυφαίους προμηθευτές που αποτελούν ηγέτες του συγκεκριμένου χώρου. Τα προϊόντα αυτά είναι:

• Φύλλα θερμής έλασης με ανάγλυφη επιφάνεια.• Μαύρα, πικλαρισμένα, φύλλα θερμής έλασης.

• Γαλβανισμένα φύλλα ψυχρής έλασης, προβαμμένης και πλαστικοποιημένης λαμαρίνας.

• Κατασκευαστικές λαμαρίνες θερμής έλασης.

• Γαλβανισμένες αυλακωτές και τραπεζοειδής λαμαρίνες.

• Επιμήκεις, γαλβανιζέ κοίλοι άβαφοι δοκοί.

• Σωλήνες.

• Πάνελα.

Σε κάθε περίπτωση, στόχος μας είναι να προσφέρουμε στον εκάστοτε πελάτη εκείνα τα στοχευμένα υλικά που ταιριάζουν απόλυτα στις ανάγκες του και να ανταποκρινόμαστε με ακρίβεια σε αυτές.

Λαμαρίνα κριθαράκι & μπακλαβωτή.

Μορφοσωλήνες - Κοιλοδοκοί

Διάτρητες λαμαρίνες

Λαμαρίνες διαφόρων ειδών & ποιοτήτων

- Θερμής έλασης

- Ψυχρής έλασης

- Γαλβανιζέ

- Αλουμίνιο

- Ανοξείδωτες

TruLaser Tube 3000 fiber : Laser Cutter τελευταίας γενιάς

Ο κόσμος εξελίσσεται. Οι υψηλοί ρυθμοί ανάπτυξης απαιτούν συνεχώς μαζική παραγωγή προϊόντων, μεγάλη ποικιλία υλικών με εμφανή μείωση του κόστους. Προϊόντα που περιλαμβάνουν μεταλλικούς σωλήνες και προφίλ χρησιμοποιούνται παντού - από τη μηχανολογία και την κατασκευή συστημάτων μέχρι τη βιομηχανία επίπλων. Τα laser cutter έχουν ανοίξει νέες δυνατότητες σχεδιασμού. Η μέθοδος κοπής σωλήνων με λέιζερ είναι πλέον μια ιδιαίτερα αποτελεσματική και ευέλικτη μέθοδος επεξεργασίας κοπής σωλήνων, με εφαρμογή σε πολλούς βιομηχανικούς κλάδους. Tα λέιζερ κοπής μετάλλων έχουν τη δυνατότητα να πραγματοποιούν κοπές προφίλ σε στρογγυλούς, τετράγωνους, οβάλ, τριγωνικούς σωλήνες. Επίσης, παρέχουν τη δυνατότητα κοπής σωλήνων και μετάλλων με μεγάλη ακρίβεια σε εξαιρετικά πολύπλοκα σχήματα. Επιπλέον, τα laser cutter προσφέρουν δυνατότητα κάθε τύπου περιγράμματος σε σωλήνες και προφίλ με τη μέγιστη δυνατή ακρίβεια και σχεδιαστική λειτουργικότητα, τέλεια ευθυγράμμιση και ευελιξία εξαιτίας της απίθανης λεπτομέρειας που μόνο τα λέιζερ κοπής μετάλλων προσφέρουν. Τέλος, τα laser cutter μπορούν να κόψουν διάφορα μέταλλα όπως κοινό χάλυβα 8mm, ανοξείδωτο ατσάλι 4mm, αλουμίνιο 4mm, χαλκό - ορείχαλκο 3mm. Έτσι, οι σχεδιαστές αυτών των προϊόντων έχουν στραφεί στην τεχνολογία κοπής σωλήνων με λέιζερ, λόγω των μοναδικών πλεονεκτημάτων που προσφέρουν. Η PANMETAL, έχοντας πλήρη γνώση της εξέλιξης αυτής, καλωσόρισε στις εγκαταστάσεις της το νέο αξιόπιστο και ακριβές λέιζερ κοπής σωλήνων, Τrulaser tube 3000 Fiber. Ένα laser cutter μηχάνημα που καλύπτει ένα ευρύ φάσμα εφαρμογών όπως προφίλ, στρογγυλούς σωλήνες και επίπεδες ράβδους ενώ ταυτόχρονα επιτρέπει την ευέλικτη επεξεργασία σωλήνων και προφίλ, αντικαθιστώντας τα συμβατικά στάδια επεξεργασίας σωλήνων, όπως τα πριόνια και τα κέντρα κατεργασίας. Το λέιζερ κοπής σωλήνων TruLaser Tube 3000 fiber μπορεί να κόψει σωλήνες με διάμετρο έως 152mm και προφίλ με εξωτερική περιφέρεια έως 170 mm. To αυτόματα κεντραριζόμενο σύστημα συγκράτησης αυτού του laser cutter, έχει σχεδιαστεί για να συγκρατεί το προϊόν στη σωστή θέση κατά την κατεργασία, ενώ προσαρμόζεται αυτόματα στις διαστάσεις του σωλήνα χωρίς να χρειάζεται κάποια χειροκίνητη ρύθμιση από τον χειριστή. Tο λέιζερ κοπής σωλήνων TruLaser Tube 3000 fiber είναι εξοπλισμένο επιπλέον και με άλλες σημαντικές αυτόματες λειτουργίες και ρυθμίσεις. Η λειτουργία AdjustLine του συγκεκριμένου λέιζερ κοπής σωλήνων προσαρμόζει τις παραμέτρους κοπής με το άγγιγμα ενός κουμπιού, για να εξασφαλίζει αξιόπιστη κοπή ακόμα και σε υλικά χαμηλότερης ποιότητας. Η λειτουργία SeamLine Tube του laser cutter TruLaser Tube 3000 fiber εντοπίζει ραφές συγκόλλησης καθώς και χαράξεις στο εσωτερικό και το εξωτερικό της επιφάνειας των σωλήνων, βοηθώντας τον χειριστή να ελέγξει αν οι σωλήνες είναι σωστά τοποθετημένες στο μηχάνημα και ότι η ραφή συγκόλλησης είναι στην επιθυμητή θέση στο τελικό προϊόν. Το μηχάνημα αυτό κοπής σωλήνων με λέιζερ, με τον δημιουργικό σχεδιασμό προφίλ, εξοικονομεί χρόνο και προσφέρει τεχνικά πλεονεκτήματα όπως: βελτιστοποίηση των επιμέρους κομματιών και των ανταλλακτικών, εξαιρετικά μεγάλη ακρίβεια, αύξηση της ταχύτητας παράδοσης και μείωση του κόστους. Ένα αξιόπιστο μηχάνημα laser cutter φιλικό προς το χρήστη που αντιπροσωπεύει οικονομική λύση για παρτίδες μεσαίου και μικρού μεγέθους. Η κοπή σωλήνων με λέιζερ είναι η προηγμένη τεχνολογία των flat μηχανημάτων. Σε συνδυασμό με το ειδικό λογισμικό του η αυτοματοποίηση των προϊόντων καλωσορίζει τη νέα γενιά των μονάδων παραγωγής.

Με ιδανική εφαρμογή σε έπιπλα, σε εξοπλισμό καταστημάτων είτε σε μεμονωμένα έργα είτε σε μαζική παραγωγή, και στη βιομηχανία, για μαζική παραγωγή εξαρτημάτων υψηλής ποιότητας, οι λύσεις αυτοματισμού του laser cutter TruLaser Tube 300 συμβάλλoυν σημαντικά στον εκσυγχρονισμό της παραγωγής αφού έτσι αντικαθίστανται οι συμβατικοί τρόποι επεξεργασίας σωλήνων και βελτιστοποιούνται πολλά στοιχεία που κατασκευάζονται παραδοσιακά από μεταλλικά ελάσματα.

Τεχνικά χαρακτηριστικά του laser cutter TruLaser Tube 3000 fiber:

Το laser cutter TruLaser Tube 3000 fiber είναι εύκολο στη χρήση με ειδικό λογισμικό. Διαθέτει εύκολα ρυθμιζόμενο στήριγμα σωλήνων για όλες τις γεωμετρίες και τις διαμέτρους. Το συγκεκριμένο λέιζερ κοπής σωλήνων επίσης, αναγνωρίζει γραμμές ραφής εξωτερικά και εσωτερικά για αυτόματη, σωστή ευθυγράμμιση σωλήνων. Τέλος, το laser cutter TruLaser Tube 3000 fiber δίνει αποτελέσματα υψηλής ποιότητας χωρίς ρυθμίσεις με αξιόπιστη σύσφιξη όλων των σωλήνων.

Για να δείτε τα τεχνικά χαρακτηριστικά του μηχανήματος πατήστε ΕΔΩ

- Αντιγραφή.jpg)